1. who are we?

We are based in Guangdong, China, start from 2006,sell to Southeast Asia(24.00%),Mid East(23.00%),Domestic Market(20.00%),South Asia(15.00%),South America(7.00%),North America(5.00%),Eastern Europe(2.00%),Eastern Asia(1.40%),Central America(0.80%),Oceania(0.50%),Western Europe(0.50%),Northern Europe(0.30%),Africa(0.30%),Southern Europe(0.20%). There are total about 101-200 people in our office.

2. how can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3.what can you buy from us?

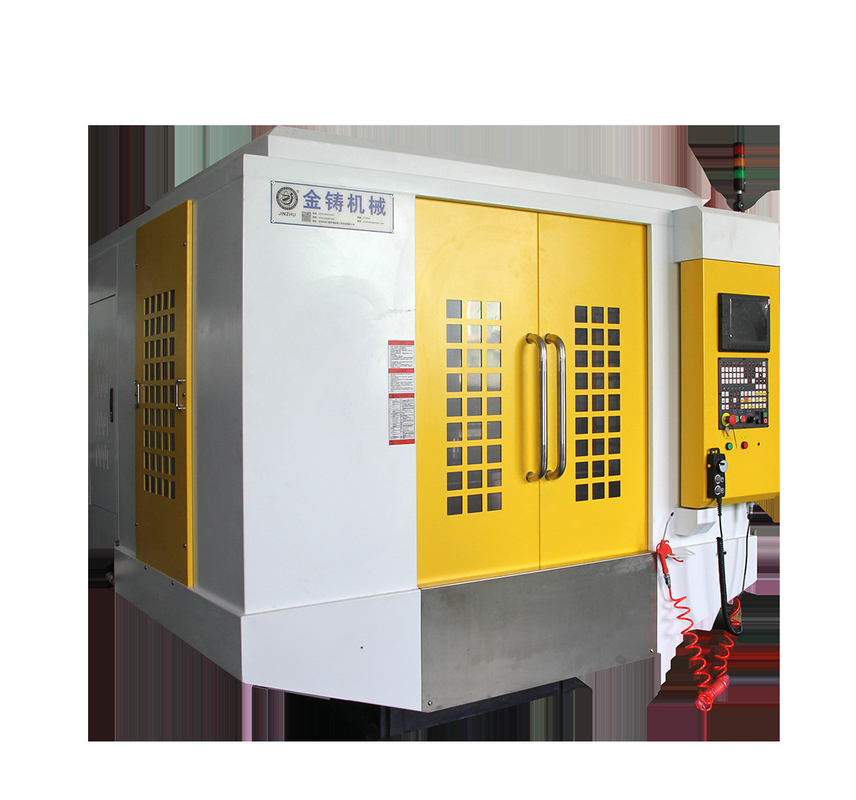

OEM & ODM,Finishing Machinessing,Polishing Machine,Deburring Machine,Buffing Machine

4. why should you buy from us not from other suppliers?

A top brand in China, since 2006. A wide range production line, with Specialized to be engaged in various types metal surface treatment machinery. A strong capacity & capability on delivery.Custiomization & Personalization are acceptable as per request.

5. what services can we provide?

Accepted Delivery Terms: FOB,CFR,CIF,EXW,FAS,CIP,FCA,CPT,DEQ,DDP,DDU,Express Delivery,DAF;

Accepted Payment Currency:USD,EUR,JPY,CAD,AUD,HKD,GBP,CNY,CHF;

Accepted Payment Type: T/T,L/C,D/P D/A,PayPal,Western Union,Cash;

Language Spoken:English,Chinese,Spanish,Japanese,Portuguese,German,Arabic,French,Russian,Korean,Hindi,Italian

Το μήνυμά σας πρέπει να αποτελείται από 20-3.000 χαρακτήρες!

Το μήνυμά σας πρέπει να αποτελείται από 20-3.000 χαρακτήρες! Παρακαλούμε ελέγξτε το email σας!

Παρακαλούμε ελέγξτε το email σας!  Το μήνυμά σας πρέπει να αποτελείται από 20-3.000 χαρακτήρες!

Το μήνυμά σας πρέπει να αποτελείται από 20-3.000 χαρακτήρες! Παρακαλούμε ελέγξτε το email σας!

Παρακαλούμε ελέγξτε το email σας!